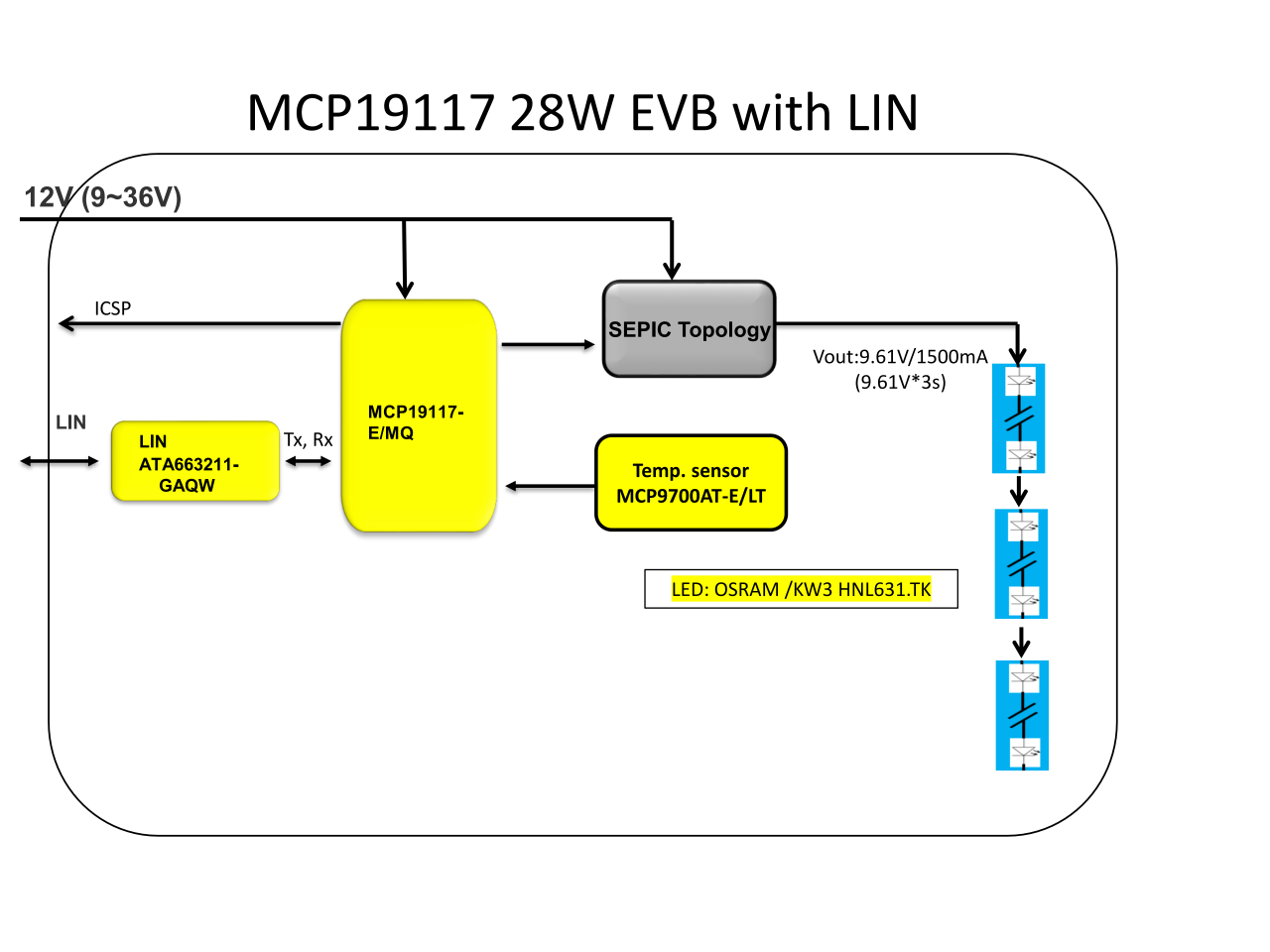

Based on MICROCHIP MCP19117 28W LED lighting solution

This solution is designed based on the external auxiliary lighting of general automobiles. It is designed using the communication interface between the aluminum substrate and LIN. The aluminum substrate can fit various heat dissipation molds. LIN can be connected with automobiles and motorcycles for control. Of course, any driver IC with Tx and Rx can control and communicate with the DEPA series, such as RS-485...etc. for various applications in industrial engineering.

DEPA (Digtal Enhanced Power Analog) itself has been highly integrated with the PWM power module, and various settings can be made through the free development software: MPLAB X IDE and MCC:

• Operating frequency, output voltage and output current,

• There is also OTP (default 125℃) inside OCP and OVP...etc.

Since it also contains an 8-bit PIC12 MCU, more flexible applications can be achieved with the assistance of programs, such as:

• Added temperature sensor MCP9700A with an accuracy of ±1°C for precise temperature control and protection.

Or use the built-in counter to control time, for example:

• Short-term high-brightness lighting, flashing, strobing...etc., it depends on the developer how to control it.

DEPA provides 8ch of 10/8bit ADC that can read external analog messages and signals, and can also perform various output or input controls through GPIO.

• For example: polling rotating warning lights, car running lights...etc.

Many people are asking: Why do we need such a large heat sink? Because traditional light bulbs burn themselves to illuminate others and dissipate heat through infrared radiation; LEDs are semiconductors that emit light and generate high heat, so they need to conduct heat to the heat sink through the aluminum substrate. The so-called cold light LED will indeed not feel heat when the distance is more than 5 cm, but it will generate amazing heat on the surface and the other side. LED is afraid of high temperatures. High temperatures will affect the life and cause light decay. The characteristics of LED are not described in this plan. Please refer to the OSRAM product line: https://ams-osram.com/

▶Scenario application diagram

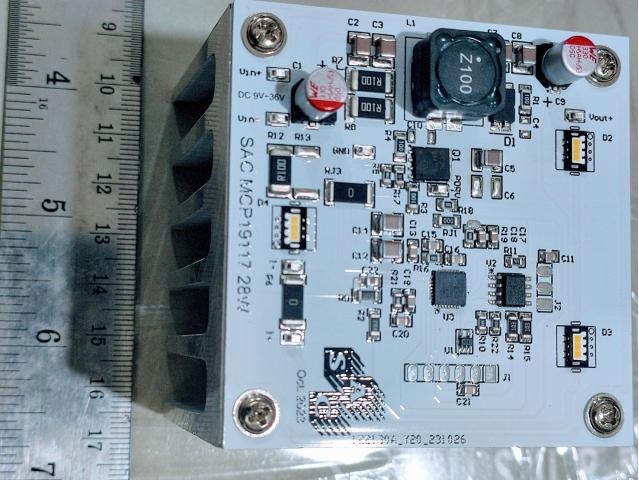

▶Display board photo

▶Solution block diagram

Core technical advantages

The DEPA chip contains an analog power controller/driver and an 8-bit MCU:

1. Has the fast response of analog power and the flexibility of digital control

2. Integrate analog components to improve loop stability

3. Optimize the circuit so that the size of the mechanism can be reduced

4. Using it is like designing a power IC yourself.

5. The device operating conditions can be read or set through internal I2C, UART or external LIN or RS485.

6. Over-temperature protection to avoid main control chip failure

7. Free development software interface, reducing power development and debugging time

8. The entire MCP19xxx series has passed AEC-Q certification

Project specifications

1.Microchip MCP9700AT-E/LT, MCP19117-E/MQ, ATA663211-GAQW

2. Input voltage range: 9V to 36V;

3. The output current is adjustable from 0.1A to 1.2A (also limited by the duty cycle);

4. 100KHZ to 800KHZ switching frequency;

5. Reduce firmware and hardware workload;

6. Programmable current limit and diaphragm mode short circuit protection;

7. Thermal shutdown with hysteresis;

8. Instantly adjustable.