L9908 gate driver: one chip with multiple functions, handling various automotive motor control

The L9908 highly integrated automotive-grade three-phase gate driver unit (GDU) is ST's star product in the field of brushless motor-related applications. It is ST's first GDU that supports 48V batteries, meeting the latest power requirements generated by the popularization of hybrid and new energy vehicles. It supports 12V, 24V or 48V automotive power systems, has flexible input and output channels, and can be used in a variety of applications on traditional gasoline vehicles and hybrid/electric new energy vehicles.

The L9908 can control six N-channel FETs to drive brushless motors in electric power steering systems, brake boosters, fans, pump motors, transmissions, etc., and fully complies with the automotive functional safety ISO26262ASIL-D standard.

Applicable to 48V automotive technology

48-volt battery

When developing new applications, engineers need to invest heavily in devices, tools, and other aspects. The importance of 48V systems in automobiles is self-evident. Larger batteries help "save fuel, reduce emissions, and increase power." Several manufacturers who have a say in the battery field also emphasize the importance of 48V batteries, but the original power system will face certain challenges when switching to 48V. The L9908 can support updated designs based on previous generation products to achieve a smooth transition.

L9908 is the next generation product of L9907, supporting 3.3V and 5V logic, and power supply voltage range as low as 4.5V. It also supports 12V, 24V, and 48V battery systems. Both L9907 and L9908 have passed AEC-Q100 certification, and L9908 meets ASIL-D standards, meeting more application requirements.

3 current sensors based on analog topology

Engineers have been committed to finding more cost-effective solutions, and analog sensing is the development direction of the industry. However, compared with floating topology, analog topology has a worse signal-to-noise ratio and a longer output stabilization time, which may affect the use of torque and complex algorithms. But customers want more powerful motor control, and drivers want a smooth steering wheel without vibration. This means engineers must develop complex algorithms and obtain high-quality data from current sensors. Therefore, despite the limitations of traditional analog topology, designers must find ways to improve performance.

The L9908 provides a unique solution that couples analog topology with digital SPI lines and uses three current sensors. The sensors provide greater flexibility and more data, and R&D personnel can adopt magnetic field control technology (FOC) to improve overall performance and efficiency. Similarly, digital SPI lines help improve the signal-to-noise ratio in signal processing and provide higher quality data to the MCU. Complex algorithms can help create more advanced steering columns without affecting the cost-effectiveness of the entire solution.

What Automakers Care Most About

Safety

In the past few years, automotive requirements for gate drivers have changed dramatically. ISO requires GDUs that support 48V applications to handle 75V supply voltages. The reason behind these changes is that smart and electric cars require stricter safety regulations to protect consumers. Therefore, the L9908 provides new diagnostic and protection functions using a 32-bit SPI interface. The safety features of the L9908 include SPI-set dead time insertion and shoot-through short-circuit diagnostic protection; open load detection, short-to-ground diagnosis, and short-to-battery diagnosis; temperature warnings can be set and junction temperature measurement data can be read through the SPI bus. Other diagnostics include ground loss detection, overvoltage and undervoltage detection of power pins and FET driver power; system clock monitoring, SPI window watchdog, and fault status flags.

Simplified prototyping

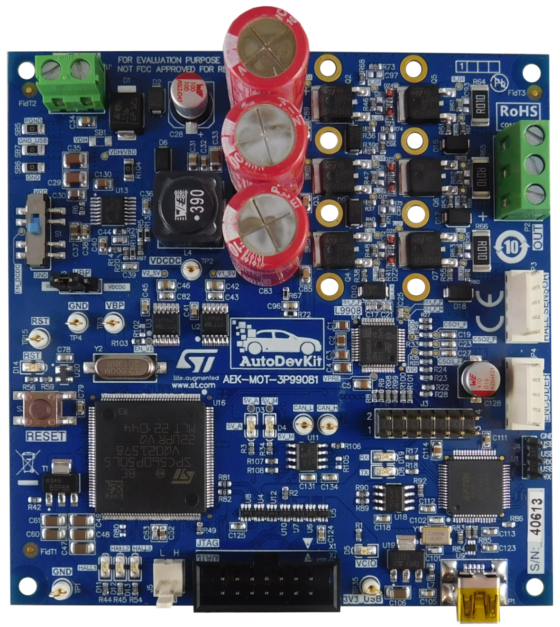

The L9908 ushers in a new era in automotive applications. To help engineers keep up with the application development trend, ST provides a variety of development boards with the L9908 and SPC560P.

The AEK-MOT-3P99081 works with the STSW-AUTODEVKIT library to help engineers prototype faster. The AutoDevKit provides a way to get a proof of concept done in minutes. The solution comes with a demo that uses the L9908 to drive a BLDC motor with a Hall sensor. ST also offers the AEK-MOT-3P9908M, a kit with a development board and motor, to further speed up development.

L9908 in various ways in automotive motor control

In applications such as low-pressure fluid pumps, air pumps and blowers in ventilation cooling systems, and electric seat control devices, the highly integrated, flexible and accurate L9908 can simplify the design, save space and improve control accuracy. The driver can also be used to design power motor inverters for mild hybrid vehicles (ICE) and 48V pure electric vehicles.

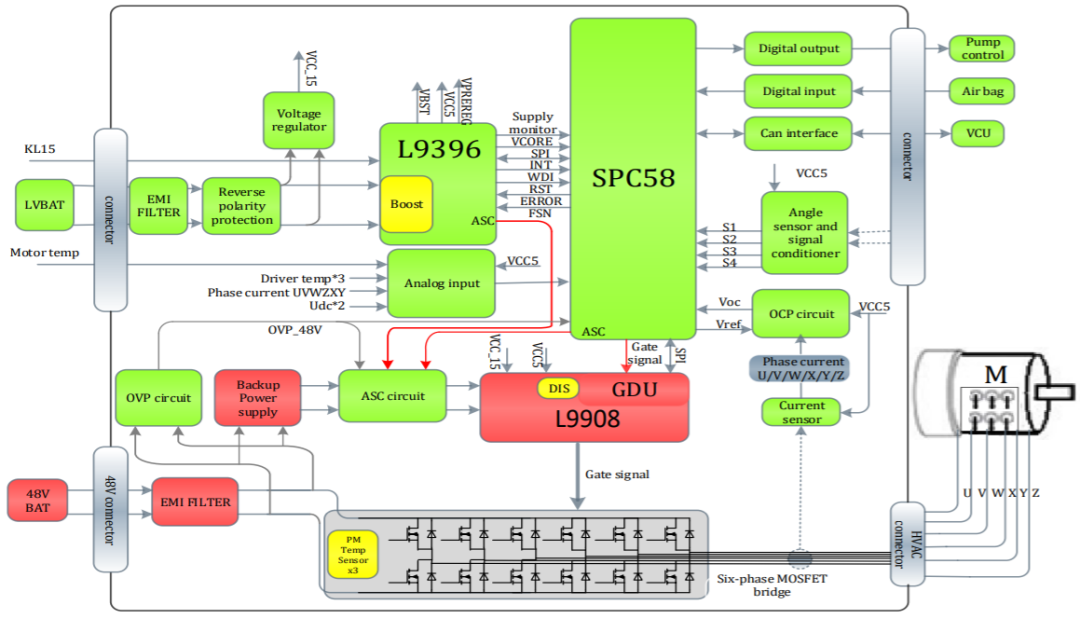

48V inverter reference design system block diagram

ST, together with the Greater Bay Area Integrated Circuit and System Application Research Institute (GIICS), has developed a 48V inverter reference design, an application solution based on ST's automotive-grade chips, including MCU (SPC58NN), SBC (L9396), Pre-Driver (L9908), analog chips, and logic protection chips.

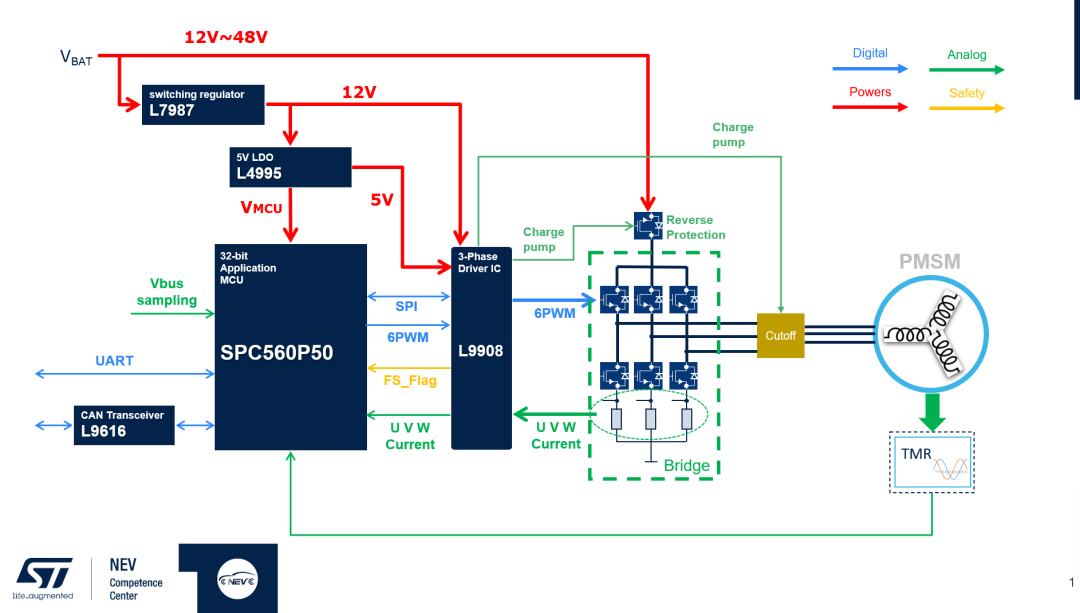

Because of its built-in diagnostic function, L9908 can also be used for safety systems such as automatic emergency braking (AEB) and advanced electric power steering (EPS), simplifying the ISO 26262 standard certification process. The following EPS demonstration solution consists of ST's automotive-grade 32-bit PowerPC architecture microprocessor SPC560P50, L9908, and automotive-grade MOS. The solution is suitable for 12V, 24V, and 48V systems, and also has corresponding diagnostic and protection functions.

In single battery (12V), dual battery (24V) and 48V automotive battery systems, the L9908 has high application flexibility because the motor power pins can withstand a wide voltage range of 4.5V to 75V, and the motor connection pins can withstand a voltage of -14V to 95V. The on-chip logic circuit uses an internal 3.3V power supply, and the digital I/O port is compatible with 3.3V and 5V logic levels.L9908 is an AEC-Q100 certified automotive grade product, now available in a thermally improved TQFP48 package.

▶Application Scenarios

▶Display board photo

▶Solution block diagram

Core technology advantages

L9908 highly integrated automotive grade three-phase gate drive unit (GDU) is ST's star product in the field of brushless motor-related applications. It is ST's first GDU that supports 48V batteries, meeting the latest power requirements generated by the popularity of hybrid and new energy vehicles. It supports 12V, 24V or 48V automotive power systems, has flexible input and output channels, and can be used in a variety of applications on traditional gasoline vehicles and hybrid/electric new energy vehicles.

Solution Specifications

• Supports 12V, 24V, 48V automotive power systems

• Power pins can withstand a wide voltage range of 4.5V to 75V

• Internal 3.3V power supply

• Digital I/O ports are compatible with 3.3V and 5V logic levels

• BLDC motor

• Motor connection pins can withstand voltages from -14V to 95V

• TQFP48 package

• AEC-Q100 certified

• ISO26262ASIL-D standard