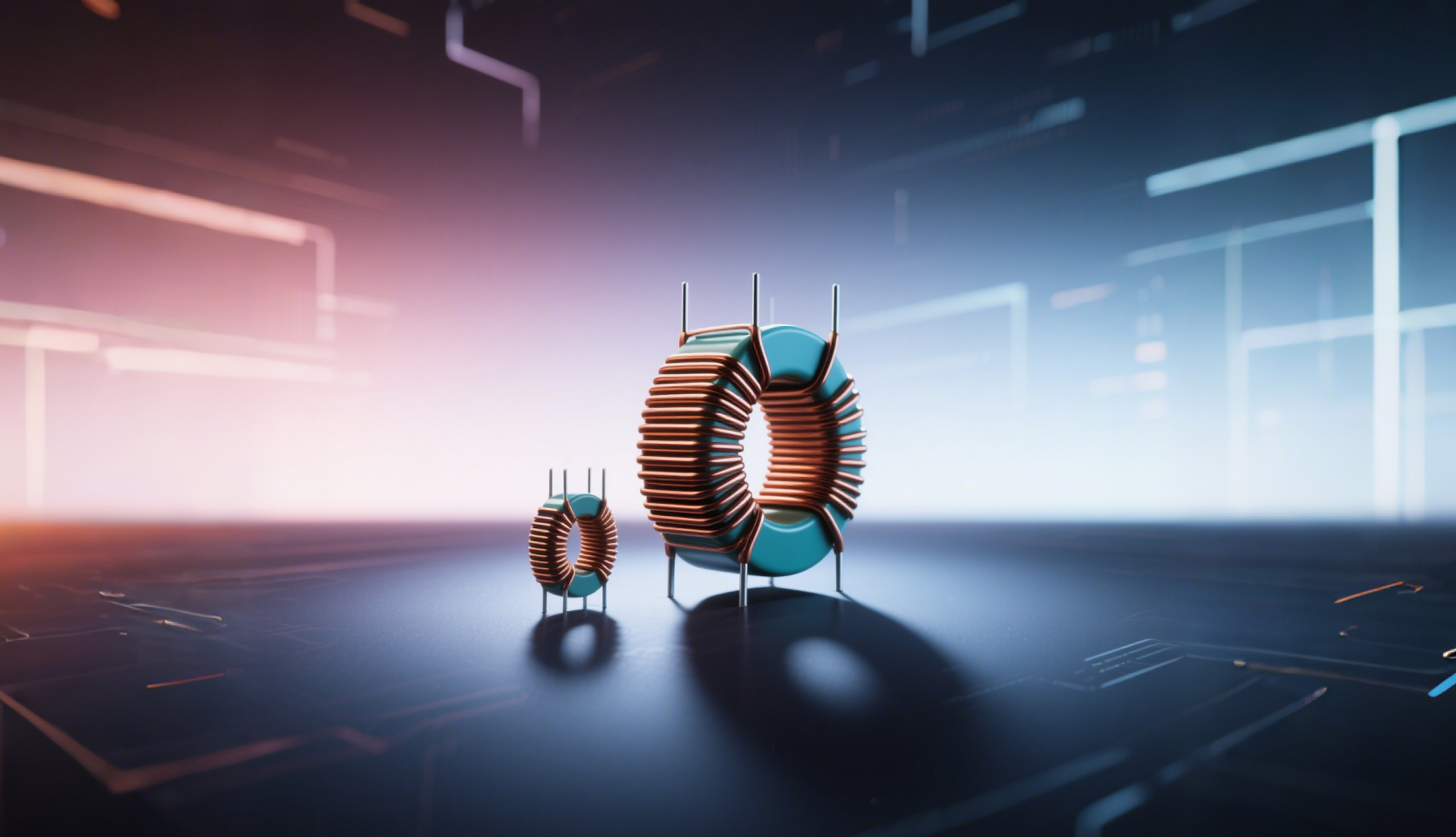

Key points for selecting common mode chokes and analysis of mainstream domestic and foreign brands

Common Mode Choke is a key component for suppressing electromagnetic interference (EMI). Its selection needs to comprehensively consider circuit characteristics, performance parameters and actual application scenarios. At the same time, it is necessary to combine the technical advantages of international manufacturers and the cost-effectiveness of domestic alternative solutions to achieve precise EMI suppression in different application scenarios.

Common Mode Choke Selection Core Parameters and Design Points

Common Mode Choke is a key component for suppressing electromagnetic interference (EMI). Its selection needs to comprehensively consider circuit characteristics, performance parameters and actual application scenarios. At the same time, it is necessary to combine the technical advantages of international manufacturers and the cost-effectiveness of domestic alternative solutions to achieve precise EMI suppression in different application scenarios. The following are the selection factors that engineers need to focus on:

Inductance value and frequency response

● Inductance value: It needs to be selected according to the filtering frequency band. Low-frequency applications (such as 150kHz-1MHz) require higher inductance values (typical value 1mH-10mH), and high-frequency applications (>10MHz) require lower inductance values (μH level). It is necessary to avoid excessive inductance values that cause signal attenuation or insufficient suppression due to too small inductance values.

● Frequency impedance characteristics: match the target frequency band through the impedance-frequency curve. For example, the power supply filter of 1MHz-30MHz needs to select a model with high high-frequency impedance

Rated current and temperature rise

● Rated current: It needs to be selected according to the maximum working current of the circuit, and the derating design should be considered (usually 1.5-2 times the actual current margin) to prevent the core saturation from causing performance degradation

● Temperature rise and DCR (DC resistance): In high current scenarios, flat copper tape winding inductors are preferred to reduce temperature rise and DCR and improve efficiency

Structural design and packaging form

● Core material and structure: Ferrite cores are suitable for high-frequency scenarios, and the ring structure (T-Core/SQ-Core) has uniform magnetic field distribution and low leakage inductance; the split winding structure needs to pay attention to the problem of magnetic saturation caused by power frequency current

● Package size: SMD type (such as 1210, 2012) is suitable for high-density PCB layout, and plug-in type is suitable for high-power scenarios

Differential mode leakage inductance and EMC compatibility

● Leakage inductance control: Excessive leakage inductance will affect the differential mode signal, but reasonable use of leakage inductance can replace differential mode inductance to reduce costs

● PCB layout optimization: The bottom of the common mode inductor needs to be hollowed out and an isolation belt needs to be set. The capacitors on both sides are connected to FG (chassis ground) and DGND (digital ground) respectively to reduce interference coupling

● Safety certification: such as UL, CE, CQC certification, medical equipment must comply with EN 60601, etc.

Analysis of mainstream domestic and foreign brands

International brand

TDK (Japan)

Advantages: excellent high-frequency characteristics, complete product line, and customized solutions;

Typical series: ACM series (automotive grade), ZJYS series (high impedance).

Murata (Japan)

Advantages: leading miniaturized chip inductor technology, suitable for communication equipment;

Typical series: DLW series (ultra-thin), LQM series (high current).

Vishay (USA)

Advantages: large current, high temperature resistance, strong industrial application;

Typical series: IHLP series (low DCR), IHCL series (automotive grade).

Würth Elektronik (Germany)

Advantages: comprehensive EMC solutions, support high-frequency design;

Typical series: WE-CMB series (wideband), WE-SL series (ultra-low loss).

Taiyo Yuden (Japan)

Advantages: strong high-frequency noise suppression capability, suitable for consumer electronics;

Typical series: NFM series (high-density patch).

Domestic brands

Sunlord

Advantages: high cost performance, fast delivery, covering consumer electronics to automotive electronics;

Typical series: MW series (general purpose), HA series (automotive grade).

Microgate

Advantages: deep layout in the 5G communication field, high-frequency performance close to Japanese brands;

Typical series: MCL series (high-frequency patch).

Fenghua Hi-Tech (FH)

Advantages: High market share in the mid- and low-end markets, and obvious cost advantages;

Typical series: TCM series (universal plug-in).

Zhenhua Fu

Advantages: Military-grade products are highly reliable and resistant to extreme environments;

Typical series: ZHC series (high withstand voltage).

Coilcraft

Advantages: Outstanding high-current inductor technology and many industrial applications;

Typical series: CSC series (high saturation current).

Selection recommendations

Consumer electronics: Prioritize small SMD models from Murata, Taiyo Yuden or Sunlord Electronics.

Industrial/automotive electronics: Choose high-reliability series from TDK, Vishay or Sunlord Electronics.

Cost-sensitive projects: Fenghua Hi-Tech and Magetech have better cost-effectiveness.

High-frequency communications (5G, USB4): high-frequency series from Würth or Magetech.

Precautions

Test verification: In actual applications, EMI testing is required to confirm the suppression effect.

Layout impact: Common Mode Choke should be placed close to the noise source to avoid introducing new interference due to long routing.

Selection trends and localization opportunities

With the breakthrough of China's domestic inductor technology, local brands have significant advantages in cost (reduced by 30%-50%), delivery time (shortened to 2-4 weeks) and service flexibility. Engineers can evaluate similar products in China when selecting solutions to achieve the best balance between performance and cost.

By combining specific application scenarios and brand characteristics, efficient selection and balance between performance and cost can be achieved.