What is a knock sensor?

1. What is Knock?

"Knock," also known as engine knocking, pinging, or detonation, refers to abnormal combustion in the engine's cylinders. Normally, the air-fuel mixture in an engine's cylinder burns in a controlled, uniform manner. However, when knocking occurs, this mixture ignites unevenly or prematurely, causing sharp, sudden pressure spikes. These pressure spikes produce a distinctive knocking or pinging noise and can lead to serious engine damage if not addressed.

2. What is a Knock Sensor?

A knock sensor is a critical component in modern internal combustion engines designed to detect and respond to engine knocking, also known as pinging. It listens for any unusual vibrations that could harm the engine and checks if the engine is running smoothly. Imagine it as a microphone, picking up on something called “spark knock.” Knocking happens when the air-fuel mixture in an engine's cylinders ignites prematurely, leading to a sudden increase in pressure that can damage the engine.

Therefore, the main function of this sensor is to monitor the ignition process inside the engine. Its indication assists the engine control to stop knocking ignition and thus guards the motor or engine control.

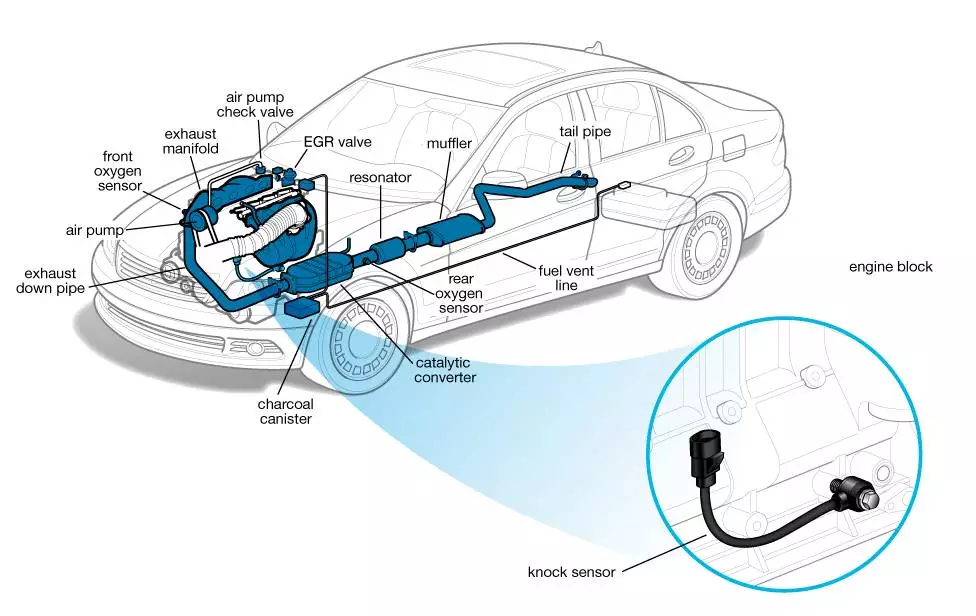

3. Where is the Knock Sensor Located?

The knock sensor is normally mounted on the outside of the engine block, but it can also be found under the intake manifold in some situations. The knock sensor is located in the engine block's midsection. As an example, consider a four-cylinder engine. It is fitted between cylinders 2 and 3, or between cylinders 1 and 2 and cylinders 3 and 4. Its purpose is to determine the degree of engine jitter and, when the engine knocks, to modify the ignition advance angle.

4. What is the Knock Sensor Working Principle?

A knock sensor plays a crucial role in modern internal combustion engines by detecting engine knocking (also known as pinging or detonation) and helping to prevent it. Here’s a detailed look at how a knock sensor works:

1. Detection of Vibrations

The knock sensor is typically made of a piezoelectric element that generates an electric signal in response to mechanical stress or vibrations. When the engine operates, various vibrations are produced. The piezoelectric material in the knock sensor is sensitive to the specific frequency range of knocking vibrations.

2. Signal Generation

When knocking occurs, the sudden pressure rise in the cylinder creates high-frequency vibrations. The piezoelectric element in the knock sensor converts these mechanical vibrations into an electrical signal. The intensity and frequency of the knocking vibrations determine the amplitude and frequency of the electrical signal generated.

3. Transmission of the Signal

The electrical signal produced by the knock sensor is transmitted to the Engine Control Unit (ECU). This signal contains information about the presence and severity of knocking.

4. ECU Analysis and Response

The ECU constantly monitors the signals from the knock sensor. When it detects a signal indicating knocking, the ECU takes action to mitigate it. The typical responses include: Retarding Ignition Timing, Adjusting Air-Fuel Ratiom, Boost Pressure Control

5. What are the Knock Sensor Symptoms?

A faulty knock sensor can lead to a variety of issues in a vehicle. Here are some common symptoms to look out for:

• Decreased Engine Performance: A malfunctioning knock sensor can send incorrect signals to the engine control unit (ECU), leading to inconsistent engine power, rough idling, and stalling.

• Poor Fuel Economy: When the knock sensor is faulty, it might cause the ECU to retard ignition timing excessively, resulting in inefficient fuel consumption and more frequent trips to the gas station.

• Warning light of the engine will be ON: The most obvious sign of a bad knock sensor is the illumination of the check engine light. Diagnostic trouble codes like P0325, P0332, and P0326 can indicate specific knock sensor issues.

• Unusual Noises: If you hear knocking or pinging sounds, especially during acceleration, it can be a sign that the knock sensor is not functioning correctly.

• Burnt Smell or Overheating: These are less common but can occur if the sensor causes improper ignition timing, leading to excessive heat.

6. What Causes Knock Sensor?

Engine knock, also known as detonation or pinging, occurs when the air-fuel mixture in an engine's cylinder ignites prematurely or unevenly, causing a sharp rise in pressure. This can lead to damage if not addressed. Here are the main causes of engine knock:

| Cause | Feature |

|---|---|

| 1. Poor Fuel Quality | Low Octane Rating, Contaminated Fuel |

| 2. Incorrect Air-Fuel Mixture | Lean Mixture, Rich Mixture |

| 3. Ignition Timing Issues | Advanced Timing, Delayed Timing |

| 4. Engine Overheating | High Temperatures, Cooling System Issues |

| 5. Carbon Deposits | Carbon Buildup |

| 6. Faulty Knock Sensor | Malfunctioning Sensor |

| 7. Mechanical Issues | Worn or Damaged Parts, Poorly Functioning EGR System |

| 8. Low Engine Oil | Inadequate Lubrication |

7. How to Replace a Knock Sensor?

Replacing a knock sensor involves locating the sensor on the engine, disconnecting the bolt, and removing the sensor and module from the locations. Then fix the new knock sensor into place the same way.

Be aware that the knock sensor is often obscured by other components on the engine block, all of which should be removed safely and carefully before starting to remove the knock sensor.

Ensure that the sensor and module are fitted back at the manufacturer’s recommended torque and that all fixtures have been replaced. Use a diagnostic tool to calibrate the sensor so the onboard computer can re-adjust to its readings. Also, clean the area where you replace the tool so the sensor can pick up a more accurate reading.